Rayons & Nylon

YARN

11220/1 D.TEX RAYON TYRE YARN

| PRODUCT :1220/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

1,240 |

± |

65 |

| 2. | No. of Filaments | - |

720 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

60 |

Min |

54 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

21840/1 D.TEX RAYON TYRE YARN

| PRODUCT :1840/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TOLERANCE | ||

| 1. | Linear Density @ 11% MR | D.Tex |

1855 |

± |

85 |

| 2. | No. of Filaments | - |

1100 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

100 |

Min |

93 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

32440/1 D.TEX RAYON TYRE YARN

| PRODUCT :2440/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

2440 |

± |

100 |

| 2. | No. of Filaments | - |

1500 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

128 |

Min |

120 |

| 5. | Elongation at break (O.D.) | % |

9.5 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

TYRE CORD

11220/1 D.TEX RAYON TYRE YARN

| PRODUCT :1220/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

1,240 |

± |

65 |

| 2. | No. of Filaments | - |

720 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

60 |

Min |

54 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

21840/1 D.TEX RAYON TYRE YARN

| PRODUCT :1840/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TOLERANCE | ||

| 1. | Linear Density @ 11% MR | D.Tex |

1855 |

± |

85 |

| 2. | No. of Filaments | - |

1100 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

100 |

Min |

93 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

32440/1 D.TEX RAYON TYRE YARN

| PRODUCT :2440/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

2440 |

± |

100 |

| 2. | No. of Filaments | - |

1500 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

128 |

Min |

120 |

| 5. | Elongation at break (O.D.) | % |

9.5 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

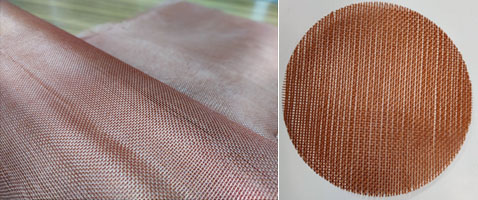

TREATED RAYON FABRIC

11220/1 D.TEX RAYON TYRE YARN

| PRODUCT :1220/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

1,240 |

± |

65 |

| 2. | No. of Filaments | - |

720 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

60 |

Min |

54 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

21840/1 D.TEX RAYON TYRE YARN

| PRODUCT :1840/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TOLERANCE | ||

| 1. | Linear Density @ 11% MR | D.Tex |

1855 |

± |

85 |

| 2. | No. of Filaments | - |

1100 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

100 |

Min |

93 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

32440/1 D.TEX RAYON TYRE YARN

| PRODUCT :2440/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

2440 |

± |

100 |

| 2. | No. of Filaments | - |

1500 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

128 |

Min |

120 |

| 5. | Elongation at break (O.D.) | % |

9.5 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

Wicking and Non-wicking : Multi Filament Nylon 6 or Nylon 66 in Deniers 840 and 1260. To customer Specification. The Yarn for the chafer can also be sourced from customers approved yarn Vendor.

11220/1 D.TEX RAYON TYRE YARN

| PRODUCT :1220/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

1,240 |

± |

65 |

| 2. | No. of Filaments | - |

720 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

60 |

Min |

54 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

21840/1 D.TEX RAYON TYRE YARN

| PRODUCT :1840/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TOLERANCE | ||

| 1. | Linear Density @ 11% MR | D.Tex |

1855 |

± |

85 |

| 2. | No. of Filaments | - |

1100 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

100 |

Min |

93 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

32440/1 D.TEX RAYON TYRE YARN

| PRODUCT :2440/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

2440 |

± |

100 |

| 2. | No. of Filaments | - |

1500 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

128 |

Min |

120 |

| 5. | Elongation at break (O.D.) | % |

9.5 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

11220/1 D.TEX RAYON TYRE YARN

| PRODUCT :1220/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

1,240 |

± |

65 |

| 2. | No. of Filaments | - |

720 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

60 |

Min |

54 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

21840/1 D.TEX RAYON TYRE YARN

| PRODUCT :1840/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TOLERANCE | ||

| 1. | Linear Density @ 11% MR | D.Tex |

1855 |

± |

85 |

| 2. | No. of Filaments | - |

1100 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

100 |

Min |

93 |

| 5. | Elongation at break (O.D.) | % |

9 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||

32440/1 D.TEX RAYON TYRE YARN

| PRODUCT :2440/1

D.TEX RAYON TYRE YARN QUALITY :SUPER-II |

|||||

| S.NO. | PROPERTIES | UNIT |

TARGET |

TOLERANCE | |

| 1. | Linear Density @ 11% MR | D.Tex |

2440 |

± |

100 |

| 2. | No. of Filaments | - |

1500 |

- |

|

| 3. | Twist ‘Z’ | Turns/Metre |

65 |

± |

5 |

| 4. | Breaking Strength(O.D.) | N |

128 |

Min |

120 |

| 5. | Elongation at break (O.D.) | % |

9.5 |

± |

1 |

| 6. | Finish | % |

0.5 |

± |

0.1 |

Testing

Machine |

INSTRON |

||

Lab.Testing

Conditions |

Temperature |

24°

C |

|

Relative

Humidity |

55% |

||

Tensile

Test Method |

ASTM

D 885 |

||